Welcome to SciencetoyMaker!

You have found the non-commercial site for people who like to roll up their sleeves and make science toys and projects. You won’t find slick web pages here–more like the digital equivalent of a messy workshop. If you poke around, though, you’ll find good stuff. Science toy maker is a resource for inspired teachers, parents, teenagers, kids, home schoolers, science fair participants and citizen scientists everywhere. >> Read More

New Stories

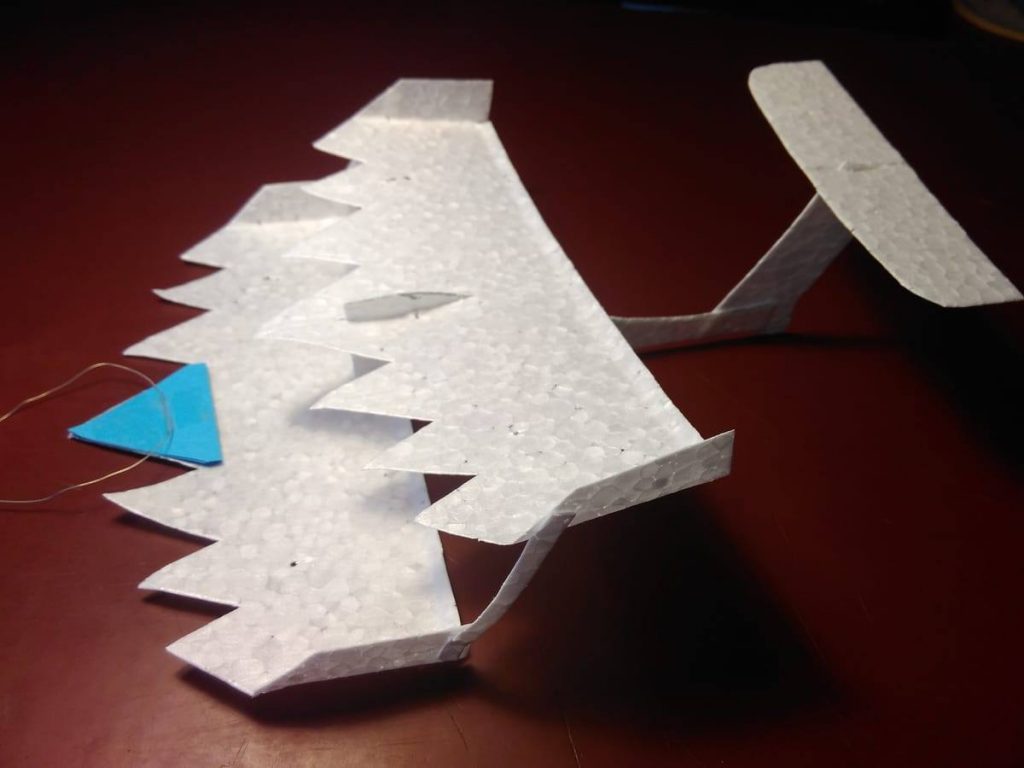

I received this picture and video from František, a young man in the Czech Republic. František cut his own foam, experimented with the Baby Bug and Thompson Jagwing gliders; and he created this elegant, charming biplane from 2 Jagwings. His glider also has a tail, and his video shows very well the challenge. If the updraft of air hits the glider more in the back or the front, then the glider dives or stalls. I have asked František to experiment with holding the board at a less steep angle and see if it is any easier to fly. David Aronstein has created many walkalong glider designs with tails, and in his interview did a great job of explaining the challenges and how to mitigate them. Thomas Buchwald , Mike Thompson and Heinrich Eder have all created cool walkalong glider designs with tails.